Wafer Handling Tool Solutions

Cost Effective & Reliable

Automated and manually activated wafer handling equipment for 75mm, 100mm, 125mm, 150mm and 200mm applications to the global semiconductor industry. Compatible with various substrate materials including Silicon Carbide (SiC) and Gallium Nitride (GaN).

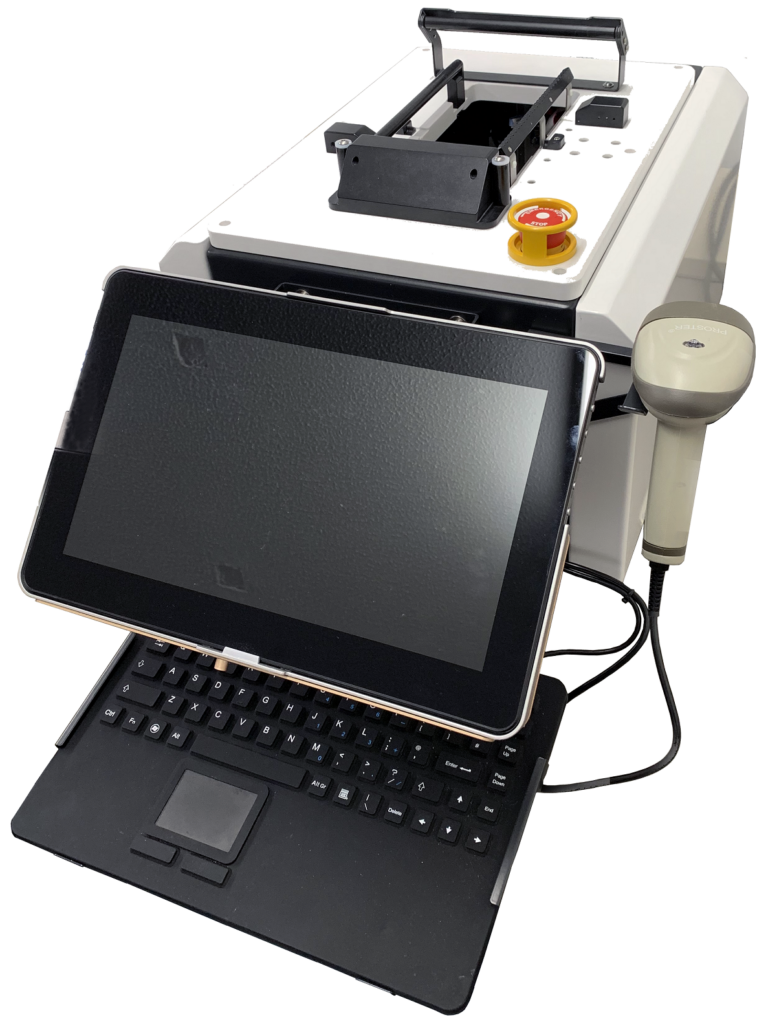

AI Wafer Inspection

Table top sorter equipment with Inspection platform to give an affordable, small footprint wafer inspection solution using cutting-edge inspection technology.

Wafer Sorter

Table top vacuum free handling to transfer and align wafers. Cassettes are mapped for wafer presence, and active safety sensors throughout the loading and transfer process.

Batch ID Reader

Read Lasermarks or Datamatrix Tags on the active and rear faces of a wafer. Wafers are aligned using EMU’s patented batch alignment system.

Batch Pick & Place

Table top, batch wafer pick & place tool that uses non-vacuum technology to transfer wafers between cassettes. Available with 1 or 2 load ports.

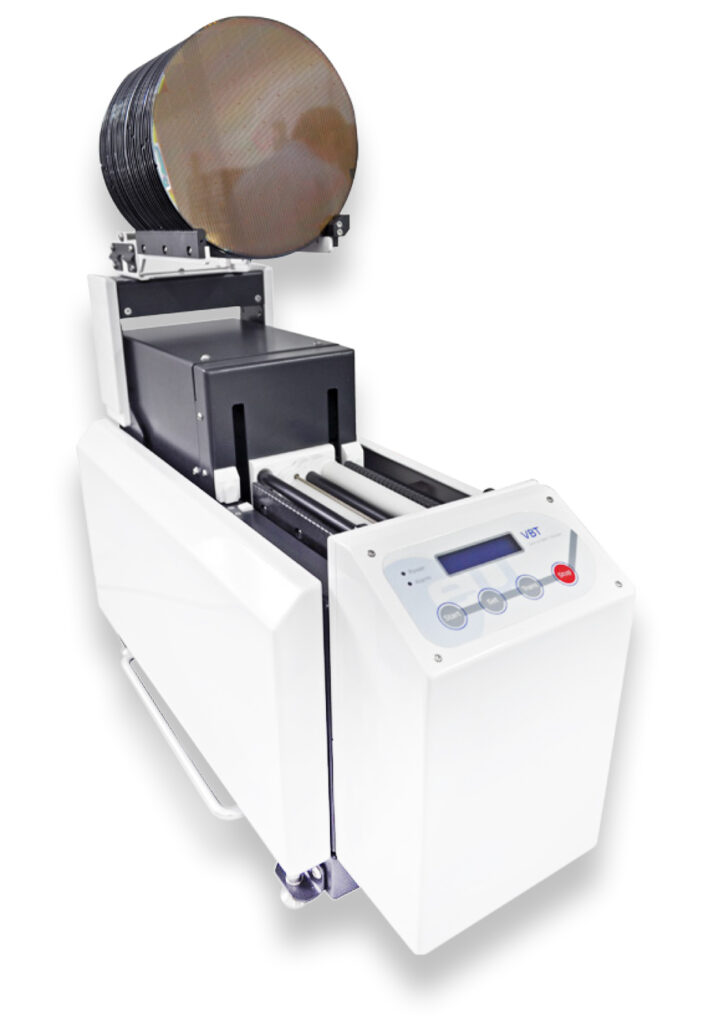

Vertical Batch Transfer

Single stage, automated tool to transfer a batch of wafers between semi-standard cassettes and align a batch of wafers by the notch or flat.

Batch Aligner & Elevator

Single stage tool that aligns wafers by the flat or notch and elevates them for inspection by the Operator.

Batch Aligner

Wafers are aligned by the flat or notch.

Batch Slide Transfer

Machines push all wafers from one cassette to another. Manual or Automated options are available.